Position Synchronized Output (PSO) Support for Industrial Laser Processing | Photonics Industries

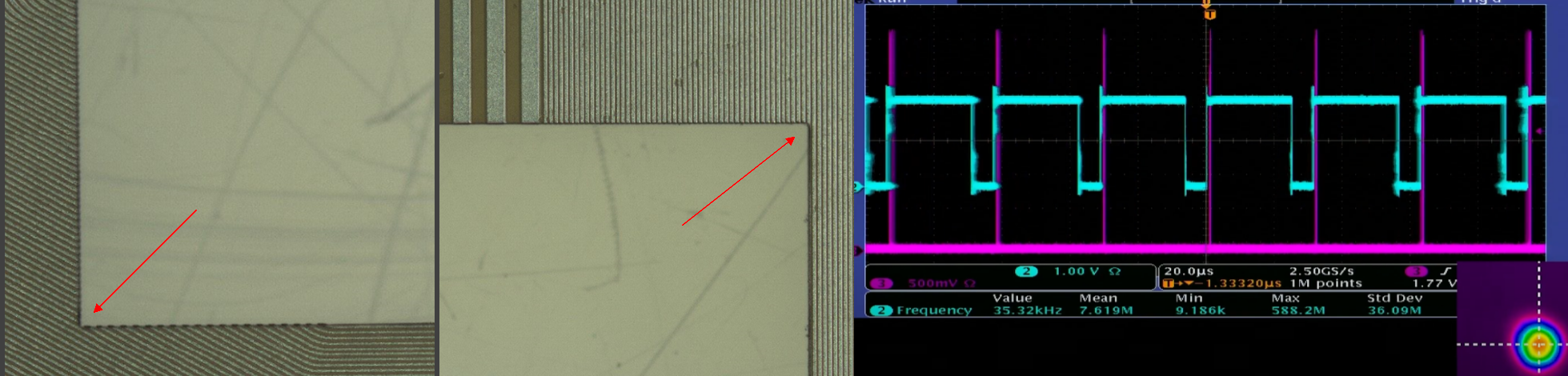

(Figure above shows the results of processing a flexible printed circuit board (FPCB) with the PSO capability. PSO supported laser processing of FPCB helps produce no charring at corners, as indicated by the red arrows, with smooth cuts and low HAZ near electrodes.)

Photonics Industries’ lasers support position synchronized output (PSO), fulfilling industrial laser processing needs:

- Increasing production throughput.

- Higher percentage yield.

- Providing consistency in quality.

PSO support capabilities include:

- Coordinate part position with process control.

- Avoidance of trigger errors based on acceleration, deceleration, or any other velocity instability.

- In this mode, the laser gives constant pulse energy regardless of trigger rate with low jitter.

- Without PSO support, the pulse energy would be higher at lower trigger rates and generate higher intensity pulses causing unwanted burring and charring (high HAZ) around corners.

With Photonics Industries PSO supported lasers, requirements associated with flexible printed circuit board (FPCB) processing (smooth edges, no burring, no charring, low HAZ, all with high cutting speeds and no damage to the electrodes) and other high precision processing applications in the electronics industry are fulfilled.

See our latest PSO supported picosecond lasers:

Watch how PSO support operates from electrical input to laser pulse output data.